Nissan Altima (L32) 2007-2012 Service Manual: Basic inspection

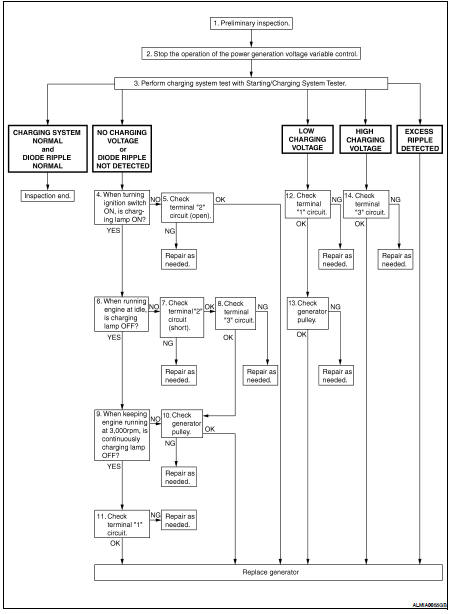

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

NOTE: To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be done as a set from start to finish.

1.PRELIMINARY INSPECTION

Perform the preliminary inspection. Refer to CHG-7, "Inspection Procedure".

>> GO TO 2

2.DISABLE THE POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

Disable the power generation voltage variable control with either of the following procedures.

• After selecting “ENGINE” on the “SELECT SYSTEM” screen of CONSULT-III, set the “ALTERNATOR DUTY” value to 0 % by selecting “ALTERNATOR DUTY” with “Active Test”. Continue “Active Test” until the end of inspection. (When the DUTY value is 0 or 100 %, the normal power generation is performed according to the characteristic of the IC regulator of the generator.) • Turn the ignition switch OFF, disconnect the battery current sensor connector and leave it disconnected during the course of the test.

NOTE: Running the engine with the battery current sensor disconnected will cause DTC's (P1550-P1554) to set.

After finishing the inspection, connect the battery current sensor connector and erase the self-diagnostic results history of the engine using CONSULT-III.

>> GO TO 3

3.DIAGNOSIS WITH STARTING/CHARGING SYSTEM TESTER

Perform the charging system test using Starting/Charging System Tester (J-44373). For details and operating instructions, refer to Technical Service Bulletin.

Test result

CHARGING SYSTEM NOMAL>>Charging system is normal and will also show “DIODE RIPPLE” test result.

NO CHARGING VOLTAGE>>GO TO 4

LOW CHARGING VOLTAGE>>GO TO 12

HIGH CHARGING VOLTAGE>>GO TO 14

HIGH CHARGING VOLTAGE>>GO TO 14 DIODE RIPPLE NORMAL>>Diode ripple is OK and will also show “CHARGING VOLTAGE” test result.

EXCESS RIPPLE DETECTED>>Replace the generator. Perform “DIODE RIPPLE” test again using Starting/ Charging System Tester (J-44373) to confirm repair.

DIODE RIPPLE NOT DETECTED>>GO TO 4

4.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

Turn the ignition switch ON.

Does the charge warning lamp illuminate? YES >> GO TO 6

NO >> GO TO 5

5.TERMINAL“2” (OPEN) CIRCUIT INSPECTION

Check terminal “2” circuit for open circuits. Refer to CHG-11, "Diagnosis Procedure".

Is the terminal “2” circuit normal? YES >> Replace generator. Refer to CHG-27, "Removal and Installation".

NO >> Repair as needed.

6.INSPECTION WITH CHARGE WARNING LAMP (IDLING)

Start the engine and run it at idle.

Does the charge warning lamp turn OFF? YES >> GO TO 9

NO >> GO TO 7

7.TERMINAL “2”(SHORT) CIRCUIT INSPECTION

Check terminal “2” circuit for short to ground. Refer to CHG-11, "Diagnosis Procedure".

Is the terminal “2” circuit normal?

YES >> GO TO 8

NO >> Repair as needed.

8.TERMINAL“3” CIRCUIT INSPECTION

Check terminal “3” circuit. Refer to CHG-12, "Diagnosis Procedure".

Is the terminal “3” circuit normal? YES >> GO TO 10

NO >> Repair as needed.

9.INSPECTION WITH CHARGE WARNING LAMP (ENGINE AT 3,000 RPM)

Increase and maintain the engine speed at 3,000 rpm.

Does the charge warning lamp remain off? YES >> GO TO 11

NO >> GO TO 10

10.INSPECTION OF GENERATOR PULLEY

Check generator pulley. Refer to CHG-29, "Inspection".

Is generator pulley normal? YES >> Replace generator. Refer to CHG-27, "Removal and Installation".

NO >> Repair as needed.

11.TERMINAL “1” CIRCUIT INSPECTION

Check terminal “1””circuit. Refer to CHG-10, "Diagnosis Procedure".

Is terminal “1” circuit normal? YES >> Replace generator. Refer to CHG-27, "Removal and Installation".

NO >> Repair as needed.

12.TERMINAL “1” CIRCUIT INSPECTION

Check terminal “1” circuit. Refer to CHG-10, "Diagnosis Procedure".

Is terminal “1” circuit normal? YES >> GO TO 13

NO >> Repair as needed.

13.INSPECTION OF GENERATOR PULLEY

Check generator pulley. Refer to CHG-29, "Inspection".

Is generator pulley normal? YES >> Replace generator. Refer to CHG-27, "Removal and Installation".

NO >> Repair as needed.

14.TERMINAL “3” CIRCUIT INSPECTION

Check terminal “3” circuit. Refer to CHG-12, "Diagnosis Procedure".

Is the terminal “3” circuit normal? YES >> Replace generator. Refer to CHG-27, "Removal and Installation".

NO >> Repair as needed.

Charging system

Charging system Function diagnosis

Function diagnosis