Nissan Altima (L32) 2007-2012 Service Manual: Intake manifold

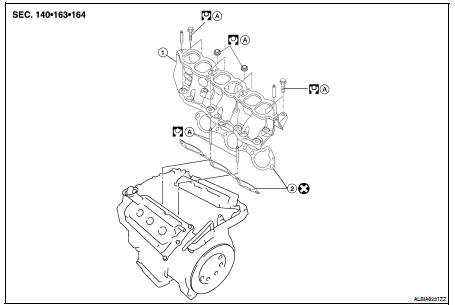

Removal and Installation

1. Intake manifold

2. Gasket

A. Follow installation procedure

REMOVAL

WARNING: To avoid the danger of being scalded, never drain the coolant when the engine is hot.

1. Remove the engine cover with power tool.

2. Release the fuel pressure. Refer to EC-1579, "Inspection".

3. Remove intake manifold collector. Refer to EM-130, "Removal and Installation".

4. Disconnect fuel tube quick connector at vehicle piping side.

5. To remove the quick connector cap, hold the sides of the connector, push in the tabs and pull out the tube.

CAUTION: • The tube can be removed when the tabs are completely depressed. Do not twist it more than necessary.

• Do not use any tools to remove the quick connector.

• Keep the resin tube away from heat. Be especially careful when welding near the tube.

• Prevent acid liquids such as battery electrolyte, etc. from getting on the resin tube.

• Do not bend or twist the tube during removal or installation.

• Do not remove the remaining retainer on the tube • When the tube is replaced, also replace the retainer with a new one.

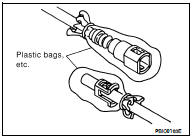

• To keep the connecting portion clean and to avoid damage and foreign materials entering, cover the ends of the fuel tubes with plastic bags or something similar.

NOTE: If the connector and the tube are stuck together, push and pull several times until they start to move. Then disconnect them by pulling.

6. Remove the fuel rail with the fuel injectors attached, from the intake manifold. Remove the fuel injector O-rings and use new O-rings for installation.

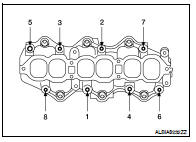

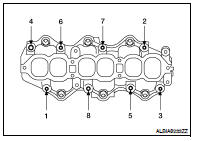

7. Loosen the bolts in the order as shown, and remove the intake manifold with power tool.

INSPECTION AFTER REMOVAL

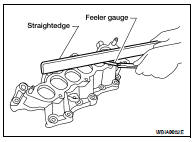

Surface Distortion

• Using straightedge and feeler gauge, inspect the surface distortion of the intake manifold. Inspect the surface distortion of the intake manifold collector. Refer to EM-130, "Removal and Installation".

Standard : 0.1 mm (0.004 in)

INSTALLATION

Installation is in the reverse order of removal. Follow the procedure below for specific tightening sequences and procedures.

• Install intake manifold bolts in two steps in the numerical order as shown.

NOTE: After installation, it is necessary to re-calibrate the electric throttle control actuator as follows: 1. Perform the "Throttle Valve Closed Position Learning" when harness connector of the electric throttle control actuator is disconnected. Refer to EC-1053, "THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement".

2. Perform the "Idle Air Volume Learning" when the electric throttle control actuator is replaced. Refer to EC- 1053, "IDLE AIR VOLUME LEARNING : Special Repair Requirement".

• Install the quick connector as follows: - Make sure no foreign substances are deposited in and around the fuel tube and quick connector and that there is no damage.

- Align the center to insert the quick connector straight onto the fuel tube.

- Insert the fuel tube until a click is heard.

- Install the quick connector cap on the quick connector joint. Align the arrow mark on the quick connector cap to the upper side.

- Install the fuel hose into the hose clamp.

INSPECTION AFTER INSTALLATION

Make sure there is no fuel leakage at connections as follows: 1. Apply fuel pressure to fuel lines by turning ignition switch ON (with engine stopped). Then check for fuel leaks at connections.

2. Start the engine and rev it up and check for fuel leaks at connections.

CAUTION: Do not touch engine immediately after stopping as engine is extremely hot.

NOTE: Use mirrors for checking on connections out of the direct line of sight.

Intake manifold collector

Intake manifold collector Exhaust manifold and three way

catalyst

Exhaust manifold and three way

catalyst