Nissan Altima (L32) 2007-2012 Service Manual: P0448 Evap canister vent control valve

Description

The EVAP canister vent control valve is located on the EVAP canister and is used to seal the canister vent.

This solenoid valve responds to signals from the ECM. When the ECM sends an ON signal, the coil in the solenoid valve is energized.

A plunger will then move to seal the canister vent. The ability to seal the vent is necessary for the on board diagnosis of other evaporative emission control system components.

This solenoid valve is used only for diagnosis, and usually remains opened.

When the vent is closed, under normal purge conditions, the evaporative emission control system is depressurized and allows “EVAP Control System” diagnosis.

DTC Logic

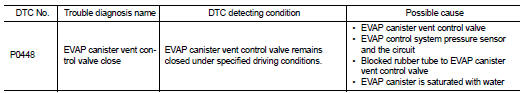

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

. Turn ignition switch ON and wait at least 5 seconds.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT-III.

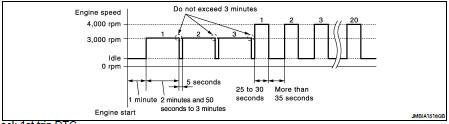

4. Start engine and let it idle for at least 1 minute.

5. Repeat next procedures 3 times.

- Increase the engine speed up to between 3,000 and 3,500 rpm and maintain that speed it for 2 minutes and 50 seconds to 3 minutes.

Never exceed 3 minutes.

- Fully released accelerator pedal and keep engine idle for approximately 5 seconds.

6. Repeat next procedure 20 times.

- Quickly increase the engine speed up to between 4,000 and 4,500 rpm and maintain that speed it for 25 to 30 seconds.

- Fully released accelerator pedal and keep engine idle for at least 35 seconds.

7. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Go to EC-1329, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK RUBBER TUBE

1. Turn ignition switch OFF.

2. Disconnect rubber tube connected to EVAP canister vent control valve.

3. Check the rubber tube for clogging.

Is the inspection result normal? YES >> GO TO 2.

NO >> Clean rubber tube using an air blower.

2.CHECK EVAP CANISTER VENT CONTROL VALVE

Refer to EC-1330, "Component Inspection".

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace EVAP canister vent control valve.

3.CHECK IF EVAP CANISTER IS SATURATED WITH WATER

1. Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor attached.

2. Check if water will drain from the EVAP canister.

Does water drain from the EVAP canister? YES >> GO TO 4.

NO >> GO TO 6.

4.CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pressure sensor attached.

The weight should be less than 2.1 kg (4.6 lb).

Is the inspection result normal? YES >> GO TO 6.

NO >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

• EVAP canister for damage

• EVAP hose between EVAP canister and vehicle frame for clogging or poor connection >> Repair hose or replace EVAP canister.

6.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR CONNECTOR

1. Disconnect EVAP control system pressure sensor harness connector.

2. Check that water is not inside connectors.

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace EVAP control system pressure sensor.

7.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

Refer to EC-1334, "Component Inspection".

Is the inspection result normal? YES >> GO TO 8.

NO >> Replace EVAP control system pressure sensor.

8.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

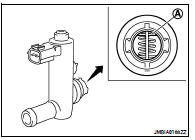

1.CHECK EVAP CANISTER VENT CONTROL VALVE-I

1. Remove EVAP canister vent control valve from EVAP canister.

2. Check portion (A) of EVAP canister vent control valve for rust.

Is it rusted? YES >> Replace EVAP canister vent control valve.

NO >> GO TO 2.

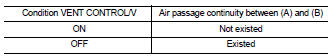

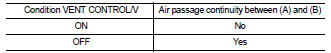

2.CHECK EVAP CANISTER VENT CONTROL VALVE-II

1. Reconnect harness connectors disconnected.

2. Turn ignition switch ON.

3. Perform “VENT CONTROL/V” in “ACTIVE TEST” mode.

4. Check air passage continuity and operation delay time.

Check that new O-ring is installed properly.

Operation takes less than 1 second.

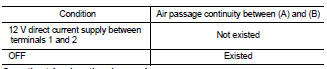

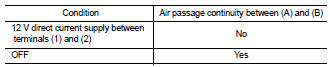

1. Disconnect EVAP canister vent control valve harness connector.

2. Check air passage continuity and operation delay time under the following conditions.

Check that new O-ring is installed properly.

Operation takes less than 1 second.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 3.

3.CHECK EVAP CANISTER VENT CONTROL VALVE-III

1. Clean the air passage [portion (A) to (B)] of EVAP canister vent control valve using an air blower.

2. Perform “VENT CONTROL/V” in “ACTIVE TEST” mode.

3. Check air passage continuity and operation delay time.

Check that new O-ring is installed properly.

Operation takes less than 1 second.

1. Clean the air passage [portion (A) to (B)] of EVAP canister vent control valve using an air blower.

2. Check air passage continuity and operation delay time under the following conditions.

Check that new O-ring is installed properly.

Operation takes less than 1 second. Is the inspection result normal? YES >> INSPECTION END

NO >> Replace EVAP canister vent control valve

P0447 Evap canister vent control valve

P0447 Evap canister vent control valve P0451 Evap control system pressure sensor

P0451 Evap control system pressure sensor