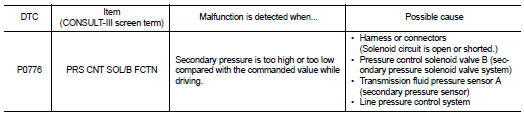

Nissan Altima (L32) 2007-2012 Service Manual: P0776 pressure control solenoid B performance (sec pressure solenoid valve)

Description

The pressure control solenoid valve B (secondary pressure solenoid valve) regulates the secondary pressure to suit the driving condition in response to a signal sent from the TCM.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION: Always drive vehicle at a safe speed. NOTE: If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn ignition switch OFF.

Then wait at least 10 seconds before performing the next test.

1.CHECK DTC DETECTION

1. Turn ignition switch ON.

2. Select “DATA MONITOR”.

3. Start engine and maintain the following conditions for at least 30 consecutive seconds.

Follow the procedure “With CONSULT-III”.

Is “P0776 PRS CNT SOL/B FCTN” detected? YES >> Go to TM-333, "Diagnosis Procedure".

NO >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

Diagnosis Procedure

1.CHECK LINE PRESSURE

Perform line pressure test. Refer to TM-423, "Inspection and Judgment".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace damaged parts. Refer to TM-423, "Inspection and Judgment".

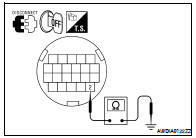

2.CHECK PRESSURE CONTROL SOLENOID VALVE B (SECONDARY PRESSURE SOLENOID VALVE)

1. Turn ignition switch OFF.

2. Disconnect CVT unit connector.

3. Check pressure control solenoid valve B (secondary pressure solenoid valve). Refer to TM-334, "Component Inspection [Pressure Control Solenoid Valve B (Secondary Pressure Solenoid Valve)]".

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace transaxle assembly. Refer to TM-447, "Exploded View".

3.CHECK PRESSURE CONTROL SOLENOID VALVE A (LINE PRESSURE SOLENOID VALVE)

Check pressure control solenoid valve A (line pressure solenoid valve). Refer to TM-334, "Component Inspection [Pressure Control Solenoid Valve A (Line Pressure Solenoid Valve)]".

Is the inspection result normal? YES >> GO TO 4.

NO >> Replace transaxle assembly. Refer to TM-447, "Exploded View".

4.CHECK TRANSMISSION FLUID PRESSURE SENSOR A (SECONDARY PRESSURE SENSOR) SYSTEM

Check transmission fluid pressure sensor A (secondary pressure sensor) system. Refer to TM-341, "DTC Logic".

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace damaged parts.

5.DETECT MALFUNCTIONING ITEMS

Check TCM connector pin terminals for damage or loose connection with harness connector.

Is the inspection result normal? YES >> Replace TCM. Refer to TM-430, "Exploded View".

NO >> Repair or replace damaged parts.

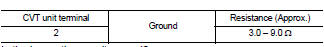

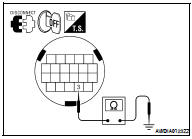

Component Inspection [Pressure Control Solenoid Valve A (Line Pressure Solenoid Valve)]

1.CHECK PRESSURE CONTROL SOLENOID VALVE A (LINE PRESSURE SOLENOID VALVE)

Check resistance between CVT unit terminal 2 and ground.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace transaxle assembly. Refer to TM-447, "Exploded View".

Component Inspection [Pressure Control Solenoid Valve B (Secondary Pressure Solenoid Valve)]

1.CHECK PRESSURE CONTROL SOLENOID VALVE B (SECONDARY PRESSURE SOLENOID VALVE)

Check resistance between CVT unit terminal 3 and ground.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace transaxle assembly. Refer to TM-447, "Exploded View".

P0746 pressure control solenoid a

performance (line pressure solenoid

valve)

P0746 pressure control solenoid a

performance (line pressure solenoid

valve) P0778 pressure control solenoid B electrical (sec pressure solenoid valve)

P0778 pressure control solenoid B electrical (sec pressure solenoid valve)