Nissan Altima (L32) 2007-2012 Service Manual: P1550 Battery current sensor

Description

The power generation voltage variable control enables fuel consumption to be decreased by reducing the engine load which is caused by the power generation of the generator. The battery current sensor is installed to the battery cable at the negative terminal. The sensor measures the charging/discharging current of the battery.

Based on the sensor signal, ECM judges whether or not the power generation voltage variable control is performed. When performing the power generation voltage variable control, ECM calculates the target power generation voltage based on the sensor signal. And ECM sends the calculated value as the power generation command value to IPDM E/R. For the details of the power generation voltage variable control, refer to CHG-6, "System Description".

CAUTION: Never connect the electrical component or the ground wire directly to the battery terminal. The connection causes the malfunction of the power generation voltage variable control, and then the battery discharge may occur.

DTC Logic

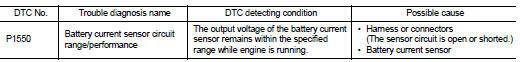

DTC DETECTION LOGIC

NOTE: If DTC P1550 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643. Refer to EC-1379, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION: Before performing the following procedure, confirm that battery voltage is more than 8 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and wait at least 10 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Go to EC-1398, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E9. Refer to Ground Inspection in GI-45, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

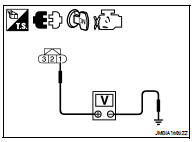

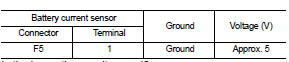

2.CHECK BATTERY CURRENT SENSOR POWER SUPPLY CIRCUIT

1. Disconnect battery current sensor harness connector.

2. Turn ignition switch ON.

3. Check the voltage between battery current sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

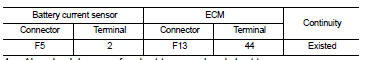

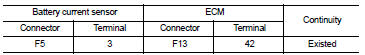

3.CHECK BATTERY CURRENT SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between battery current sensor harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

4.CHECK BATTERY CURRENT SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between battery current sensor harness connector and ECM harness connector.

2. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

5.CHECK BATTERY CURRENT SENSOR

Refer to EC-1399, "Component Inspection".

Is the inspection result normal? YES >> GO TO 6.

NO >> Replace battery negative cable assembly.

6.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

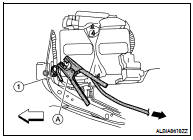

1.CHECK BATTERY CURRENT SENSOR

1. Turn ignition switch OFF.

2. Reconnect harness connectors disconnected.

3. Disconnect battery negative cable (1).

4. Install jumper cable (A) between battery negative terminal and body ground.

5. Turn ignition switch ON.

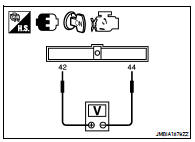

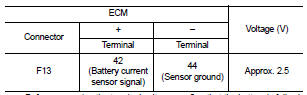

6. Check the voltage between ECM harness connector terminals under the following conditions.

Before measuring the terminal voltage, confirm that the battery is fully charged.

Refer to PG-3, "How to Handle Battery".

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace battery negative cable assembly.

P1421 Cold start control

P1421 Cold start control P1551, P1552 Battery current sensor

P1551, P1552 Battery current sensor