Nissan Altima (L32) 2007-2012 Service Manual: P2119 electric throttle control actuator

Description

Electric throttle control actuator consists of throttle control motor, throttle position sensor, etc.

The throttle control motor is operated by the ECM and it opens and closes the throttle valve.

The throttle position sensor detects the throttle valve position, and the opening and closing speed of the throttle valve and feeds the voltage signals to the ECM. The ECM judges the current opening angle of the throttle valve from these signals and the ECM controls the throttle control motor to make the throttle valve opening angle properly in response to driving condition.

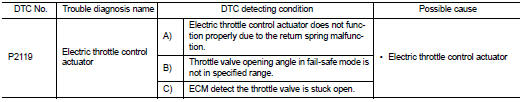

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION A AND B

1. Turn ignition switch ON and wait at least 1 second.

2. Set shift lever to D (CVT) or 1st (M/T) position and wait at least 3 seconds.

3. Set shift lever to P (CVT) or Neutral (M/T) position.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Turn ignition switch ON and wait at least 1 second.

6. Set shift lever to D (CVT) or 1st (M/T) position and wait at least 3 seconds.

7. Set shift lever to P (CVT) or Neutral (M/T) position.

8. Turn ignition switch OFF, wait at least 10 seconds, and then turn ON.

9. Check DTC.

Is DTC detected? YES >> Go to EC-425, "Diagnosis Procedure".

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE FOR MALFUNCTION C

1. Turn ignition switch ON and wait at least 1 second.

2. Set shift lever to D (CVT) or 1st (M/T) position and wait at least 3 seconds.

3. Set shift lever to N, P (CVT) or Neutral (M/T) position.

4. Start engine and let it idle for 3 seconds.

5. Check DTC.

Is DTC detected? YES >> Go to EC-425, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK ELECTRIC THROTTLE CONTROL ACTUATOR VISUALLY

1. Turn ignition switch OFF.

2. Remove the intake air duct.

3. Check if foreign matter is caught between the throttle valve (1) and the housing.

2. Electric throttle control actuator

Is the inspection result normal? YES >> GO TO 2.

NO >> Remove the foreign matter and clean the electric throttle control actuator inside.

2.REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1. Replace electric throttle control actuator.

2. Go to EC-426, "Special Repair Requirement".

>> INSPECTION END

Special Repair Requirement

1.PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Refer to EC-29, "THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement" >> GO TO 2.

2.PERFORM IDLE AIR VOLUME LEARNING

Refer to EC-30, "IDLE AIR VOLUME LEARNING : Special Repair Requirement" >> END

P2118 throttle control motor

P2118 throttle control motor P2122, P2123 APP sensor

P2122, P2123 APP sensor