Nissan Altima (L32) 2007-2012 Service Manual: Power supply and ground circuit

Diagnosis Procedure

1.INSPECTION START

Start engine.

Is engine running? YES >> GO TO 8.

NO >> GO TO 2.

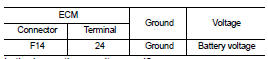

2.CHECK ECM POWER SUPPLY CIRCUIT-I

1. Turn ignition switch OFF and then ON.

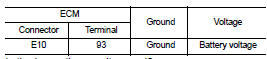

2. Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• IPDM E/R harness connector E18

• 10A fuse (No. 35)

• Harness for open or short between ECM and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK GROUND CONNECTION-I

1. Turn ignition switch OFF.

2. Check ground connection E9. Refer to Ground Inspection in GI-45, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace ground connection.

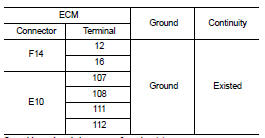

5.CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-I

1. Disconnect ECM harness connectors.

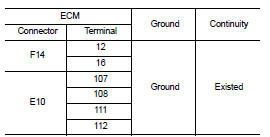

2. Check the continuity between ECM harness connector and ground.

3. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 7.

NO >> GO TO 6.

6.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors F2, E11

• Harness for open or short between ECM and ground

>> Repair open circuit or short to power in harness or connectors.

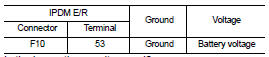

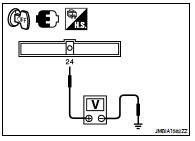

7.CHECK ECM POWER SUPPLY CIRCUIT-II

1. Reconnect ECM harness connectors.

2. Turn ignition switch ON.

3. Check the voltage between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> Go to EC-963, "Diagnosis Procedure".

NO >> GO TO 8.

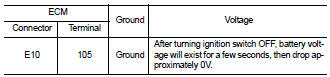

8.CHECK ECM POWER SUPPLY CIRCUIT-III

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> GO TO 14.

NO-1 >> Battery voltage does not exist: GO TO 9.

NO-2 >> Battery voltage exists for more than a few seconds: GO TO 12.

9.CHECK ECM POWER SUPPLY CIRCUIT-IV

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> GO TO 10.

NO >> GO TO 12.

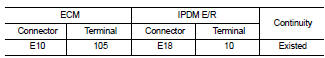

10.CHECK ECM POWER SUPPLY CIRCUIT-V

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector E18.

3. Check the continuity between ECM harness connector and IPDM E/R harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 17.

NO >> GO TO 11.

11.DETECT MALFUNCTIONING PART

Check the following.

• Junction block connectors E44, E45

• Harness for open or short between ECM and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors.

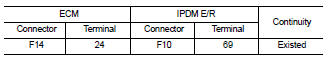

12.CHECK ECM POWER SUPPLY CIRCUIT-VI

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector F10.

3. Check the continuity between ECM harness connector and IPDM E/R harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 13.

NO >> Repair open circuit or short to ground or short power in harness or connectors.

13.CHECK 15A FUSE

1. Disconnect 15A fuse (No. 42) from IPDM E/R.

2. Check 15A fuse.

Is the inspection result normal? YES >> GO TO 17.

NO >> Replace 15A fuse.

14.CHECK GROUND CONNECTION-II

1. Turn ignition switch OFF.

2. Check ground connection E9. Refer to Ground Inspection in GI-45, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 15.

NO >> Repair or replace ground connection.

15.CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-II

1. Disconnect ECM harness connector.

2. Check the continuity between ECM harness connector and ground.

3. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 17.

NO >> GO TO 16.

16.DETECT MALFUNCTIONING PART

Check the following.

• Harness or connectors F2, E11

• Harness for open or short between ECM and ground

>> Repair open circuit or short to power in harness or connectors.

17.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

Is the inspection result normal? YES >> Replace IPDM E/R.

NO >> Repair open circuit or short to power in harness or connectors.

Trouble diagnosis - specification

value

Trouble diagnosis - specification

value U0101 Can comm circuit

U0101 Can comm circuit